Product & Service

Strain Gauge

Brand Introduce

Showa, the first strain gauge manufacturer who managed strain gauges in commercial basis and taught strain gauge techniques to provide 2 Japanese makers, such as Kyowa and TML around 50 years ago and is selling strain gauges to famous manufacturing companies such as GE worldwide and TOYOTA in domestic who are using Showa's gauges much more than other suppliers in Japan at present, was founded in 1969. The quality is absolutely worth being trusted. Hoping Chief SI will work with you together with Showa products soon.

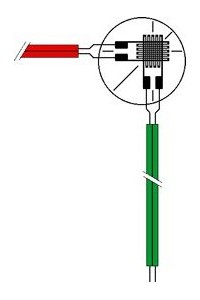

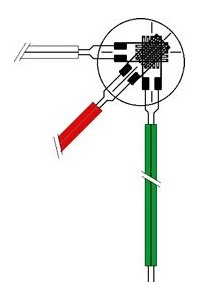

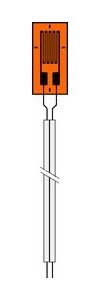

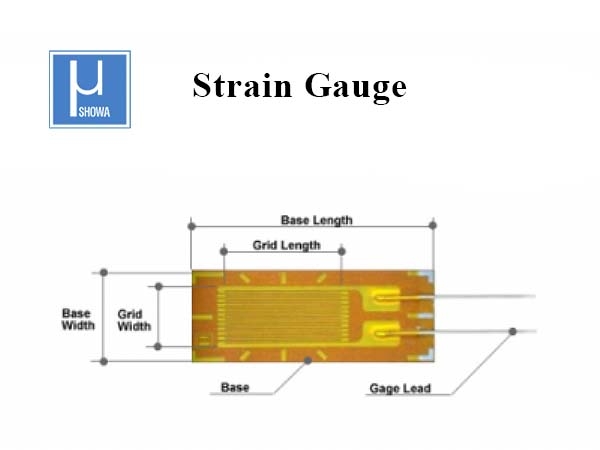

Basic Structure

Standard Specifications

The following table is given to show the classification in accordance with the difference in materials of the strain gauges grid holding base. We classify the gauges into two categories.

One is the Polyester FA series, another is the Polyimide MA series. The FA series have abundant kinds of types and specifications and therefore are suitable for a wide range of strain measurements in general. On the other hand, the MA series is suitable for strain measurement at medium and high temperatures and for the use as the elements in various industrial or scientific sensors.

|

Specification |

FA Series |

MA Series |

Unit and Note |

|

Gauge Length |

0.3mm to 60mm |

0.3mm to 60mm |

Standard |

|

Gauge Resistance |

Within±0.3%of the nominal resistance |

Within±0.3%of the nominal resistance |

120Ω to 1000Ω |

|

Foil Material |

A: Cu-Ni Alloy |

A: Cu-Ni Alloy |

|

|

Base Material |

Polyester |

Polyimide |

|

|

Gage Factor |

2.00(Nominal) |

2.00(Nominal) |

1.90 to 2.10 |

|

Measurable Strain |

2 to 4% maximum |

2 to 4% maximum |

Up to 10% with yielding strain |

|

Temperature Range |

-30℃ to +80℃ |

-30℃ to +180℃ |

|

|

Thermal Output |

±2μst/℃(RT to +80℃) |

±2μst/℃(RT to +160℃) ±5μst/℃(+160℃ to higher) |

Compensated temperature range |

|

Gauge Factor Change with Temperature |

±0.015%/℃ |

±0.015%/℃ |

Refer to“Tech information” |

|

Fatigue Life |

More than 1×10^5 reversals |

More than 1×10^5 reversals |

at ±1000×10^6 strain |

|

Applicable Linear Expansion Coefficient |

Common steel Stainless steel Aluminum alloy |

Common steel Stainless steel Aluminum alloy |

10.8ppm/℃ 16.2ppm/℃ 23.4ppm/℃ |

Configuration

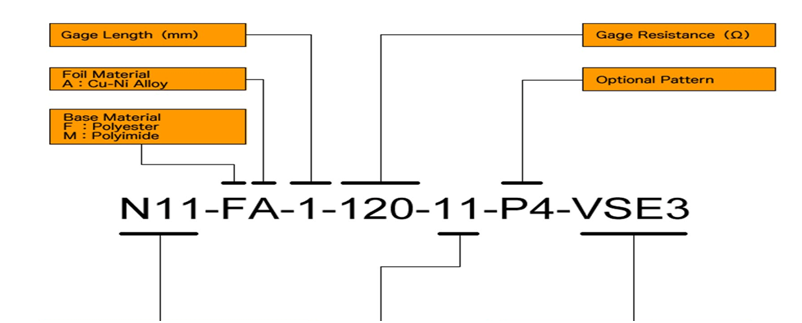

Based on the basic characteristics of strain gauges such as the material, grid shape, grid length, gauge factor, nominal resistance, material against which strain gauge is self-temperature compensated, and so on.

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- These are the basic strain gages to be used for stress measurement

|

Kinds |

Uniaxial Strain Gages |

Biaxial Strain Gages |

Triaxial Strain Gages |

Stress Concentration Measurement |

|

Pattern Code |

N11 |

N22 |

N32 |

R11, N51, R51… |

|

Lead wire pre-attached |

N11…VS… |

N22…VS… |

N32…VS… |

R11, N51, R51…VS… |

|

Basic pattern |

|

|

|

|

- These are the basic strain gages to be used for stress measurement

|

Kinds |

Uniaxial 45° |

Crack Detection |

Pipe Gage |

|

Purpose |

Shearing stress and torque measurement |

Crack propagation detection and analysis |

Bolt spindle power measurement |

|

Pattern Code |

Z11… |

X11… |

P11… |

|

Basic pattern |

|

|

|

Type

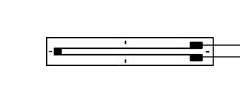

- General Purpose

- For normal temperature (FA type)

- For high temperature (MA type)

- 5 stations gauge with lead wire

- Resin coated copper wire gauge

- Crack gauge with lead wire

General Purpose

|

Strain Gage Pattern |

Type |

Nominal Resistance |

Apporox Gage Fator |

Dimension(mm) |

|||

|

Grid |

Base |

||||||

|

Length |

Width |

Length |

Width |

||||

|

|

N11-FA-03-120-(11) |

120 |

1.9 |

0.3 |

1.8 |

3.5 |

2.5 |

|

N11-FA-1-120-(11) |

120 |

2.0 |

1.0 |

1.5 |

4.0 |

2.5 |

|

|

N11-FA-1-120-(11)-P4 |

120 |

2.0 |

1.0 |

1.0 |

4.0 |

2.0 |

|

|

N11-FA-1-350-(11) |

350 |

2.0 |

1.0 |

2.4 |

5.0 |

4.0 |

|

|

N11-FA-2-120-(11) |

120 |

2.0 |

2.0 |

1.6 |

6.0 |

2.5 |

|

|

N11-FA-2-350-(11) |

350 |

2.0 |

2.0 |

2.2 |

7.0 |

3.5 |

|

|

N11-FA-3-120-(11) |

120 |

2.1 |

3.0 |

1.6 |

7.0 |

2.8 |

|

|

N11-FA-5-120-(11) |

120 |

2.1 |

5.0 |

1.8 |

9.5 |

3.5 |

|

|

N11-FA-5-350-(11) |

350 |

2.1 |

5.0 |

2.6 |

11.0 |

4.0 |

|

|

N11-FA-5-1000-(11) |

1000 |

2.1 |

5.0 |

3.2 |

9.5 |

5.0 |

|

|

N11-FA-8-120-(11) |

120 |

2.1 |

8.0 |

2.0 |

13.0 |

4.0 |

|

|

N11-FA-8-350-(11) |

350 |

2.1 |

8.0 |

4.0 |

14.0 |

6.0 |

|

|

N11-FA-10-120-(11) |

120 |

2.1 |

10.0 |

2.2 |

15.0 |

5.0 |

|

|

N11-FA-10-350-(11) |

350 |

2.1 |

10.0 |

4.5 |

18.0 |

6.5 |

|

|

N11-FA-10-600-(11) |

600 |

2.1 |

10.0 |

3.0 |

16.0 |

5.0 |

|

|

N11-FA-10-1000-(11) |

1000 |

2.0 |

10.0 |

4.5 |

16.0 |

6.0 |

|

|

N11-FA-30-120-(11) |

120 |

2.1 |

30.0 |

1.2 |

40.0 |

4.5 |

|

|

N11-MA-03-120-(11) |

120 |

1.9 |

0.3 |

1.8 |

3.5 |

2.5 |

|

|

N11-MA-1-120-(11) |

120 |

2.0 |

1.0 |

1.5 |

4.0 |

2.5 |

|

|

N11-MA-1-120-(11)-P4 |

120 |

2.0 |

1.0 |

1.0 |

4.0 |

2.0 |

|

|

N11-MA-1-350-(11) |

350 |

2.0 |

1.0 |

2.4 |

5.0 |

4.0 |

|

|

N11-MA-2-120-(11) |

120 |

2.0 |

2.0 |

1.6 |

6.0 |

2.5 |

|

|

N11-MA-2-350-(11) |

350 |

2.0 |

2.0 |

2.2 |

7.0 |

3.5 |

|

|

N11-MA-3-120-(11) |

120 |

2.1 |

3.0 |

1.6 |

7.0 |

2.8 |

|

|

N11-MA-5-120-(11) |

120 |

2.1 |

5.0 |

1.8 |

9.5 |

3.5 |

|

|

N11-MA-5-350-(11) |

350 |

2.1 |

5.0 |

2.6 |

11.0 |

4.0 |

|

|

N11-MA-5-1000-(11) |

1000 |

2.1 |

5.0 |

3.2 |

9.5 |

5.0 |

|

|

N11-MA-8-120-(11) |

120 |

2.1 |

8.0 |

2.0 |

13.0 |

4.0 |

|

|

N11-MA-8-350-(11) |

350 |

2.1 |

8.0 |

4.0 |

14.0 |

6.0 |

|

|

N11-MA-10-120-(11) |

120 |

2.1 |

10.0 |

2.2 |

15.0 |

5.0 |

|

|

N11-MA-10-350-(11) |

350 |

2.1 |

10.0 |

4.5 |

18.0 |

6.5 |

|

|

N11-MA-10-600-(11) |

600 |

2.1 |

10.0 |

3.0 |

16.0 |

5.0 |

|

|

N11-MA-10-1000-(11) |

1000 |

2.0 |

10.0 |

4.5 |

16.0 |

6.0 |

|

|

|

|||||||

|

N22-FA-1-120-(11,16,23) |

120 |

2.0 |

1.0 |

1.5 |

Φ6.0 |

||

|

N22-FA-2-120-(11,16,23) |

120 |

2.0 |

2.0 |

1.6 |

Φ8.0 |

||

|

N22-FA-5-120-(11,16,23) |

120 |

2.1 |

5.0 |

1.8 |

Φ11.0 |

||

|

N22-FA-5-350-11 |

350 |

2.1 |

5.0 |

2.6 |

Φ15.0 |

||

|

N22-FA-8-120-(11,16,23) |

120 |

2.1 |

8.0 |

2.0 |

Φ15.0 |

||

|

N22-FA-10-120-(11,16,23) |

120 |

2.1 |

10.0 |

2.2 |

Φ18.0 |

||

|

N22-MA-1-120-(11,16,23) |

120 |

2.0 |

1.0 |

1.5 |

Φ6.0 |

||

|

N22-MA-2-120-(11,16,23) |

120 |

2.0 |

2.0 |

1.6 |

Φ8.0 |

||

|

N22-MA-5-120-(11,16,23) |

120 |

2.1 |

5.0 |

1.8 |

Φ11.0 |

||

|

N22-MA-5-350-11 |

350 |

2.1 |

5.0 |

2.6 |

Φ15.0 |

||

|

|

N32-FA-1-120-(11,16,23) |

120 |

2.0 |

1.0 |

1.5 |

Φ6.0 |

|

|

N32-FA-2-120-(11,16,23) |

120 |

2.0 |

2.0 |

1.6 |

Φ8.0 |

||

|

N32-FA-5-120-(11,16,23) |

120 |

2.1 |

5.0 |

1.8 |

Φ11.0 |

||

|

N32-FA-5-350-11 |

350 |

2.1 |

5.0 |

2.6 |

Φ16.0 |

||

|

N32-FA-8-120-(11,16,23) |

120 |

2.1 |

8.0 |

2.0 |

Φ16.0 |

||

|

N32-FA-10-120-(11,16,23) |

120 |

2.1 |

10.0 |

2.2 |

Φ18.0 |

||

|

N32-MA-2-120-(11,16,23) |

120 |

2.0 |

2.0 |

1.6 |

Φ8.0 |

||

|

N32-MA-5-120-(11,16,23) |

120 |

2.1 |

5.0 |

1.8 |

Φ11.0 |

||

|

N32-MA-5-350-11 |

350 |

2.1 |

5.0 |

2.6 |

Φ16.0 |

||

|

|

N51-FA-1-120-(11,16,23) |

120 |

2.0 |

1.0, |

1.5 |

12.0 |

4.0 |

|

N51-FA-2-120-(11,16,23) |

120 |

2.0 |

2.0 |

1.6 |

15.0 |

6.0 |

|

|

N51-MA-1-120-(11,16,23) |

120 |

2.0 |

1.0 |

1.5 |

12.0 |

4.0 |

|

|

N51-MA-2-120-(11,16,23) |

120 |

2.0 |

2.0 |

1.6 |

15.0 |

6.0 |

|

|

|

R11-FA-1-120-(11,16,23) |

120 |

2.0 |

1.0 |

2.2 |

5.5 |

3.0 |

|

R11-FA-2-120-(11,16,23) |

120 |

2.0 |

2.0 |

1.8 |

6.0 |

3.5 |

|

|

R11-MA-1-120-(11,16,23) |

120 |

2.0 |

1.0 |

2.2 |

5.5 |

3.0 |

|

|

R11-MA-2-120-(11,16,23) |

120 |

2.0 |

2.0 |

1.8 |

6.0 |

3.5 |

|

|

|

R51-FA-03-120-(11,16,23)-P4 |

120 |

2.0 |

0.3 |

1.2 |

6.0 |

5.0 |

|

R51-FA-1-120-(11,16,23) |

120 |

2.0 |

1.0 |

0.5 |

11.0 |

4.0 |

|

|

R51-FA-2-120-(11,16,23) |

120 |

2.0 |

2.0 |

0.8 |

15.0 |

4.5 |

|

|

R51-MA-03-120-(11,16,23)-P4 |

120 |

2.0 |

0.3 |

1.2 |

6.0 |

5.0 |

|

|

R51-MA-1-120-(11,16,23) |

120 |

2.0 |

1.0 |

0.5 |

11.0 |

4.0 |

|

|

R51-MA-2-120-(11,16,23) |

120 |

2.0 |

2.0 |

0.8 |

15.0 |

4.5 |

|

|

|

T24-FA-2-120-(11,16,23) |

120 |

2.0 |

2.0 |

2.5 |

8.0 |

6.0 |

|

T24-FA-5-120-(11,16,23) |

120 |

2.1 |

5.0 |

6.0 |

20.0 |

15.0 |

|

|

T24-FA-5-350-11 |

350 |

2.1 |

5.0 |

6.0 |

20.0 |

15.0 |

|

|

T24-MA-2-120-(11,16,23) |

120 |

2.0 |

2.0 |

2.5 |

8.0 |

6.0 |

|

|

T24-MA-5-120-(11,16,23) |

120 |

2.1 |

5.0 |

6.0 |

20.0 |

15.0 |

|

|

T24-MA-5-350-11 |

350 |

2.1 |

5.0 |

6.0 |

20.0 |

15.0 |

|

|

|

Z11-FA-1-120-(11,16,23) |

120 |

2.0 |

1.0 |

3.9 |

5.0 |

2.5 |

|

Z11-FA-2-120-(11,16,23) |

120 |

2.0 |

2.0 |

4.0 |

13.0 |

5.0 |

|

|

Z11-FA-5-120-11 |

120 |

2.0 |

5.0 |

2.6 |

15.0 |

10.0 |

|

|

Z11-FA-10-120-11 |

120 |

2.1 |

10.0 |

5.0 |

26.0 |

16.0 |

|

|

Z11-MA-1-120-(11,16,23) |

120 |

2.0 |

1.0 |

3.9 |

5.0 |

2.5 |

|

|

Z11-MA-2-120-(11,16,23) |

120 |

2.0 |

2.0 |

4.0 |

13.0 |

5.0 |

|

|

Z11-MA-5-120-11 |

120 |

2.0 |

5.0 |

2.6 |

15.0 |

10.0 |

|

|

Z11-MA-10-120-11 |

120 |

2.1 |

10.0 |

5.0 |

26.0 |

16.0 |

|

|

|

P11-FA-05-120-11 |

120 |

1.9 |

0.5 |

--- |

Φ1.0×3.0 |

|

|

P11-FA-2-120-11 |

120 |

2.1 |

2.0 |

--- |

Φ1.5×7.0 |

||

|

P11-FA-3-120-11 |

120 |

2.1 |

3.0 |

--- |

Φ2.0×10.0 |

||

|

P11-MA-3-120-11 |

120 |

2.1 |

3.0 |

--- |

Φ2.0×10.0 |

||

For normal temperature (FA type)

|

Strain Gage Pattern |

Type |

Nominal Resistance |

Apporox Gage Fator |

Dimension(mm) |

Leadwire Length |

|||

|

Grid |

Base |

|||||||

|

Length |

Width |

Length |

Width |

|||||

|

|

N11-FA-03-120-(11)-VSE03 |

120 |

1.9 |

0.3 |

1.8 |

3.5 |

2.5 |

0.3 |

|

N11-FA-03-120-(11)-VSE1 |

120 |

1.9 |

0.3 |

1.8 |

3.5 |

2.5 |

1.0 |

|

|

N11-FA-03-120-(11)-VSE3 |

120 |

1.9 |

0.3 |

1.8 |

4.0 |

2.0 |

3.0 |

|

|

N11-FA-03-120-(11)-VSE5 |

120 |

1.9 |

0.3 |

1.8 |

4.0 |

2.0 |

5.0 |

|

|

N11-FA-1-120-(11)-P4-VSE03 |

120 |

2.0 |

1.0 |

1.0 |

4.0 |

2.0 |

0.3 |

|

|

N11-FA-1-120-(11)-P4-VSE1 |

120 |

2.0 |

1.0 |

1.0 |

4.0 |

2.0 |

1.0 |

|

|

N11-FA-1-120-(11)-P4-VSE3 |

120 |

2.0 |

1.0 |

1.0 |

4.0 |

2.0 |

3.0 |

|

|

N11-FA-1-120-(11)-P4-VSE5 |

120 |

2.0 |

1.0 |

1.0 |

4.0 |

2.0 |

5.0 |

|

|

N11-FA-2-120-(11)-VSE03 |

120 |

2.0 |

2.0 |

1.6 |

6.0 |

2.5 |

0.3 |

|

|

N11-FA-2-120-(11)-VSE1 |

120 |

2.0 |

2.0 |

1.6 |

6.0 |

2.5 |

1.0 |

|

|

N11-FA-2-120-(11)-VSE3 |

120 |

2.0 |

2.0 |

1.6 |

6.0 |

2.5 |

3.0 |

|

|

N11-FA-2-120-(11)-VSE5 |

120 |

2.0 |

2.0 |

1.6 |

6.0 |

2.5 |

5.0 |

|

|

N11-FA-5-120-(11)-VSE03 |

120 |

2.1 |

5.0 |

1.8 |

9.5 |

3.5 |

0.3 |

|

|

N11-FA-5-120-(11)-VSE1 |

120 |

2.1 |

5.0 |

1.8 |

9.5 |

3.5 |

1.0 |

|

|

N11-FA-5-120-(11)-VSE3 |

120 |

2.1 |

5.0 |

1.8 |

9.5 |

3.5 |

3.0 |

|

|

N11-FA-5-120-(11)-VSE5 |

120 |

2.1 |

5.0 |

1.8 |

9.5 |

3.5 |

5.0 |

|

|

|

N22-FA-1-120-(11)-VS03 |

120 |

2.0 |

1.0 |

1.5 |

Φ6.0 |

0.3 |

|

|

N22-FA-1-120-(11)-VS1 |

120 |

2.0 |

1.0 |

1.5 |

Φ6.0 |

1.0 |

||

|

N22-FA-1-120-(11)-VS3 |

120 |

2.0 |

1.0 |

1.5 |

Φ6.0 |

3.0 |

||

|

N22-FA-1-120-(11)-VS5 |

120 |

2.0 |

1.0 |

1.5 |

Φ6.0 |

5.0 |

||

|

N22-FA-2-120-(11)-VS03 |

120 |

2.0 |

2.0 |

1.6 |

Φ8.0 |

0.3 |

||

|

N22-FA-2-120-(11)-VS1 |

120 |

2.0 |

2.0 |

1.6 |

Φ8.0 |

1.0 |

||

|

N22-FA-2-120-(11)-VS3 |

120 |

2.0 |

2.0 |

1.6 |

Φ8.0 |

3.0 |

||

|

N22-FA-2-120-(11)-VS5 |

120 |

2.0 |

2.0 |

1.6 |

Φ8.0 |

5.0 |

||

|

N22-FA-5-120-(11)-VS03 |

120 |

2.1 |

5.0 |

1.8 |

Φ11.0 |

0.3 |

||

|

N22-FA-5-120-(11)-VS1 |

120 |

2.1 |

5.0 |

1.8 |

Φ11.0 |

1.0 |

||

|

N22-FA-5-120-(11)-VS3 |

120 |

2.1 |

5.0 |

1.8 |

Φ11.0 |

3.0 |

||

|

N22-FA-5-120-(11)-VS5 |

120 |

2.1 |

5.0 |

1.8 |

Φ11.0 |

5.0 |

||

|

|

N32-FA-1-120-(11)-VS03 |

120 |

2.0 |

1.0 |

1.5 |

Φ6.0 |

0.3 |

|

|

N32-FA-1-120-(11)-VS1 |

120 |

2.0 |

1.0 |

1.5 |

Φ6.0 |

1.0 |

||

|

N32-FA-1-120-(11)-VS3 |

120 |

2.0 |

1.0 |

1.5 |

Φ6.0 |

3.0 |

||

|

N32-FA-1-120-(11)-VS5 |

120 |

2.0 |

1.0 |

1.5 |

Φ6.0 |

5.0 |

||

|

N32-FA-2-120-(11)-VS03 |

120 |

2.0 |

2.0 |

1.6 |

Φ8.0 |

0.3 |

||

|

N32-FA-2-120-(11)-VS1 |

120 |

2.0 |

2.0 |

1.6 |

Φ8.0 |

1.0 |

||

|

N32-FA-2-120-(11)-VS3 |

120 |

2.0 |

2.0 |

1.6 |

Φ8.0 |

3.0 |

||

|

N32-FA-2-120-(11)-VS5 |

120 |

2.0 |

2.0 |

1.6 |

Φ8.0 |

5.0 |

||

|

N32-FA-5-120-(11)-VS03 |

120 |

2.1 |

5.0 |

1.8 |

Φ11.0 |

0.3 |

||

|

N32-FA-5-120-(11)-VS1 |

120 |

2.1 |

5.0 |

1.8 |

Φ11.0 |

1.0 |

||

|

N32-FA-5-120-(11)-VS3 |

120 |

2.1 |

5.0 |

1.8 |

Φ11.0 |

3.0 |

||

|

N32-FA-5-120-(11)-VS3 |

120 |

2.1 |

5.0 |

1.8 |

Φ11.0 |

5.0 |

||

For high temperature (MA type)

|

Strain Gage Pattern |

Type |

Nominal Resistance |

Apporox Gage Fator |

Dimension(mm) |

Leadwire Length |

|||

|

Grid |

Base |

|||||||

|

Length |

Width |

Length |

Width |

|||||

|

|

N11-MA-03-120-(11)-FE3 |

120 |

1.9 |

0.3 |

1.8 |

3.5 |

2.5 |

3.0 |

|

N11-MA-1-120-(11)-P4-FE3 |

120 |

2.0 |

1.0 |

1.0 |

4.0 |

2.0 |

3.0 |

|

|

N11-MA-2-120-(11)-FE3 |

120 |

2.0 |

2.0 |

1.6 |

6.0 |

2.5 |

3.0 |

|

|

N11-MA-5-120-(11)-FE3 |

120 |

2.1 |

5.0 |

1.8 |

9.5 |

3.5 |

3.0 |

|

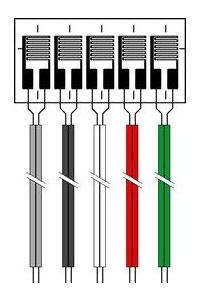

5 stations gauge with lead wire

|

Strain Gage Pattern |

Type |

Nominal Resistance |

Apporox Gage Fator |

Dimension(mm) |

Leadwire Length |

|||

|

Grid |

Base |

|||||||

|

Length |

Width |

Length |

Width |

|||||

|

|

R51-FA-1-120-11-VM3(Lead wire 5 colors) |

120 |

2.0 |

1.0 |

0.5 |

11.0 |

4.0 |

3.0 |

Resin coated copper wire gauge

|

Strain Gage Pattern |

Type |

Nominal Resistance |

Apporox Gage Fator |

Dimension(mm) |

Leadwire Length |

|||

|

Grid |

Base |

|||||||

|

Length |

Width |

Length |

Width |

|||||

|

|

N11-FA-1-120-11-P4-L05 |

120 |

2.0 |

1.0 |

1.0 |

4.0 |

2.0 |

0.5 |

|

N11-FA-2-120-11-L05 |

120 |

2.0 |

2.0 |

1.6 |

6.0 |

2.5 |

0.5 |

|

|

|

Z11-FA-1-120-11-L05 |

120 |

2.0 |

1.0 |

3.9 |

5.0 |

2.5 |

0.5 |

|

Z11-FA-1-120-11-L08 |

120 |

2.0 |

1.0 |

3.9 |

5.0 |

2.5 |

0.8 |

|

|

Z11-FA-1-120-11-L1 |

120 |

2.0 |

1.0 |

3.9 |

5.0 |

2.5 |

1.0 |

|

|

|

Y11-FA-2-120-11-L05 |

120 |

2.0 |

2.0 |

1.7 |

7.5 |

3.5 |

0.5 |

|

|

R51-FA-1-120-11-L03 |

120 |

2.0 |

1.0 |

0.5 |

11.0 |

4.0 |

0.3 |

|

|

N51-FA-1-120-11-L03 |

120 |

2.0 |

1.0 |

1.5 |

12.0 |

4.0 |

0.3 |

Crack gauge with lead wire

|

Strain Gage Pattern |

Type |

Nominal Resistance |

Apporox Gage Fator |

Dimension(mm) |

Leadwire Length |

|||

|

Grid |

Base |

|||||||

|

Length |

Width |

Length |

Width |

|||||

|

|

X11-FA-5-120-VSE3 |

120 |

--- |

5.0 |

1.7 |

11.0 |

4.0 |

3.0 |

|

X11-FA-10-120-VS3 |

120 |

--- |

10.0 |

0.25 |

14.0 |

3.0 |

3.0 |

|

|

X11-FA-30-120-VSE3 |

120 |

--- |

30.0 |

0.7 |

35.0 |

4.0 |

3.0 |

|

|

X11-FA-30-120-VS3 |

120 |

--- |

30.0 |

0.7 |

35.0 |

4.0 |

3.0 |

|

Other types of gauges can be downloaded on the icon of spec. at the upper right on this web page.

Or, if you require the ability for special use, it is welcome to contact us.

If you are interesting this products, please download the catalog now. A sales representative will contact with you as soon as possible

© 2019 Chief SI INC. - Design By Armlet