Product & Service

Electrical Actuator Fatigue/Static Test System

Multi-function

Capable of testing various bicycle parts in one machine:

- Frame (horizontal/vertical force by single actuator, pedaling force by dual actuators)

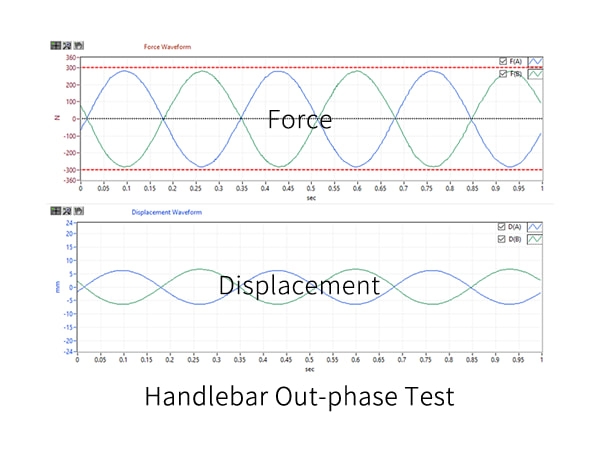

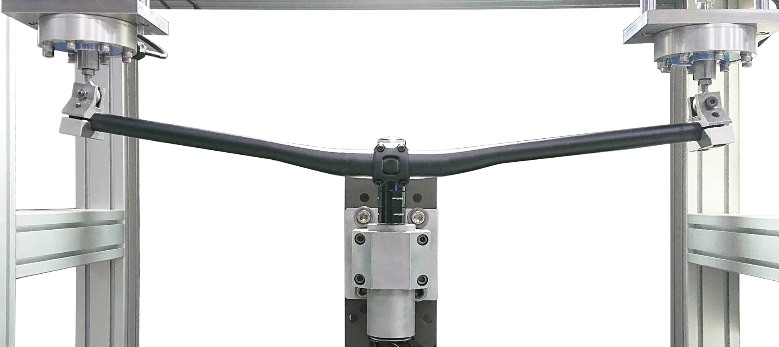

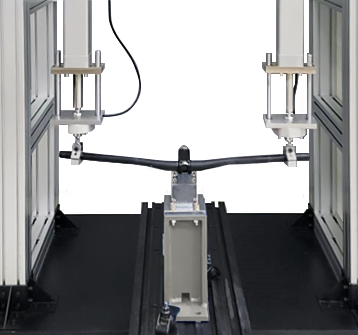

- Handlebar and stem (out-phase or in-phase force by dual actuators)

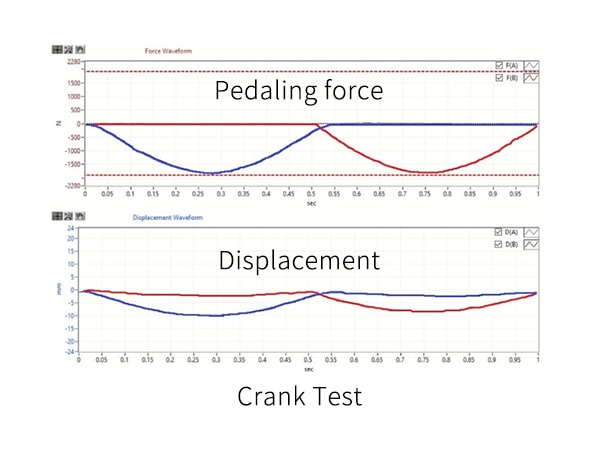

- Crankset (pedaling force by dual actuators)

- Seat post (vertical force by single actuator)

- Fork (vertical force by single actuator)

- Fork and stem assembly (single force or out-phase force by dual actuators)

Test modes

- Fatigue test conforming to ISO 4210: 2023

- Static pressure holding test

- Auto multi-stage test (continuing handlebar out-phase/in-phase test)

- Crack detect mode: part crack check by slow motion control

Advantage

- Plug and play, just need 220Vac power

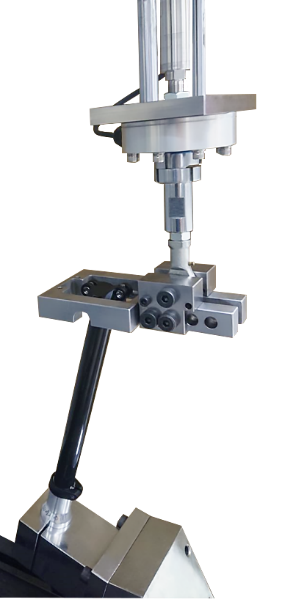

- Capability of installing vertically, inclinedly, or horizontally

- Compact actuator size, easy disassembly and movement

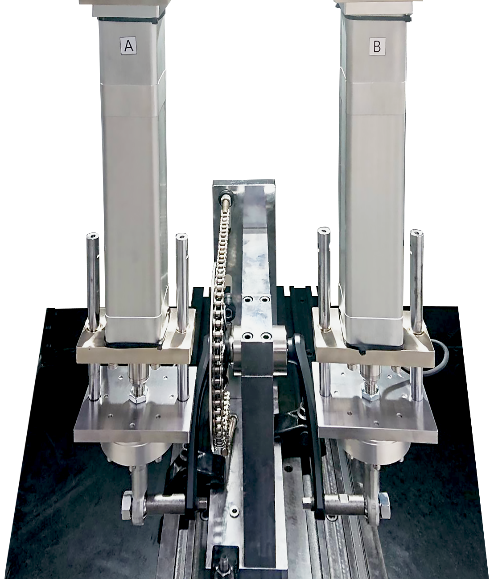

- Quick release design for easy moving actuator left/right and up/down

- Energy saving and less carbon emissions: power consumption less than 4 kW

- Low noise/pollution: noise less than 75dBA

- Simple maintenance: 3 years guarantee for actuator, easy replacement by users

- High efficient real-time control in 4kHz/actuator control loop, without disturbing by Windows operation

- Small machine size

- Large testing space

Rich software functions

- Simple, intuitive and clear information user interface

- Chinese/English interface

- Auto actuator zero-force tracking, convenient for installing testing parts

- Smart PID control for different part stiffness

- Setting of auto multi-stage test

- Test resume: test can resume from interrupt or temporarily stop

- Provide force and displacement real-time graph

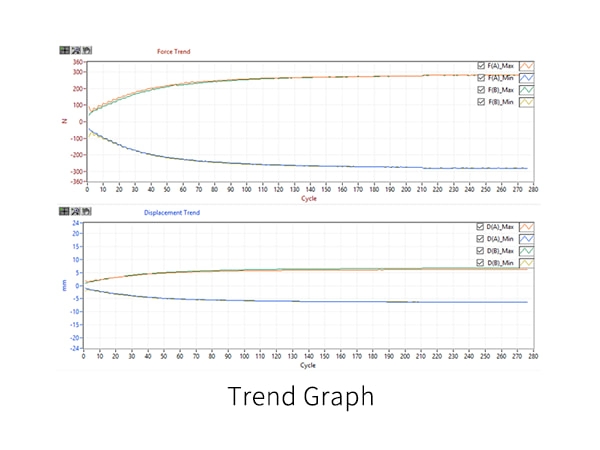

- Provide force and displacement trend graph

- Record testing waveform and trend PDF format test report

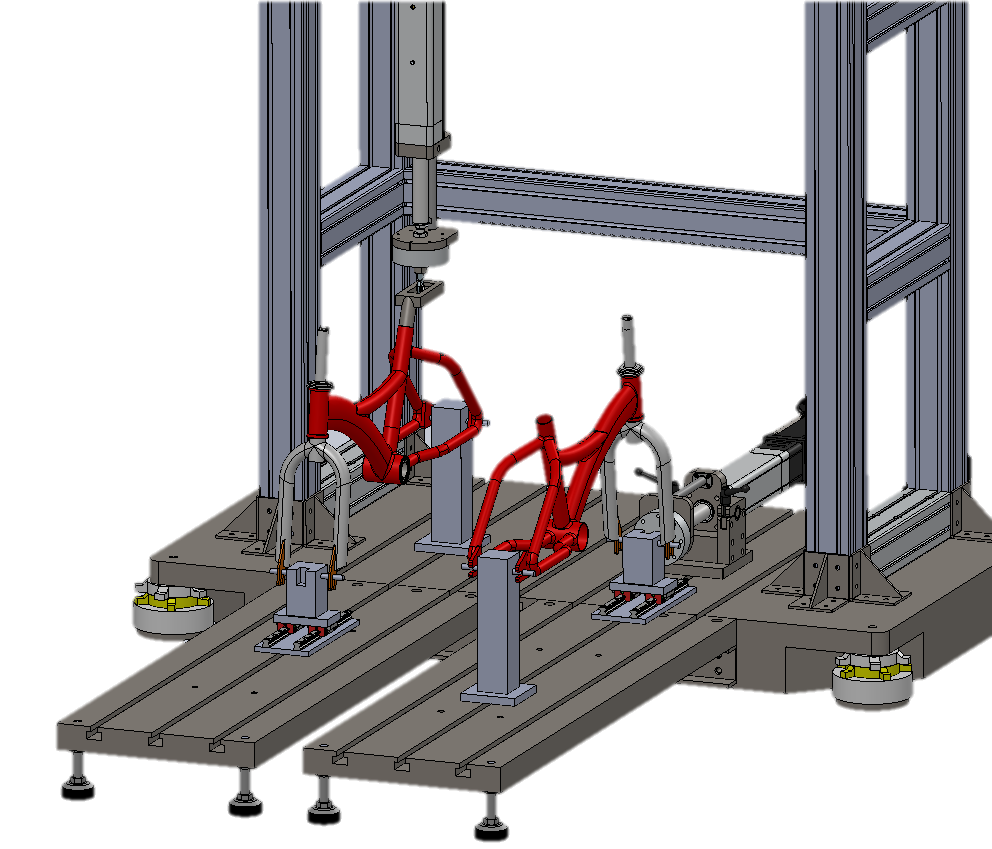

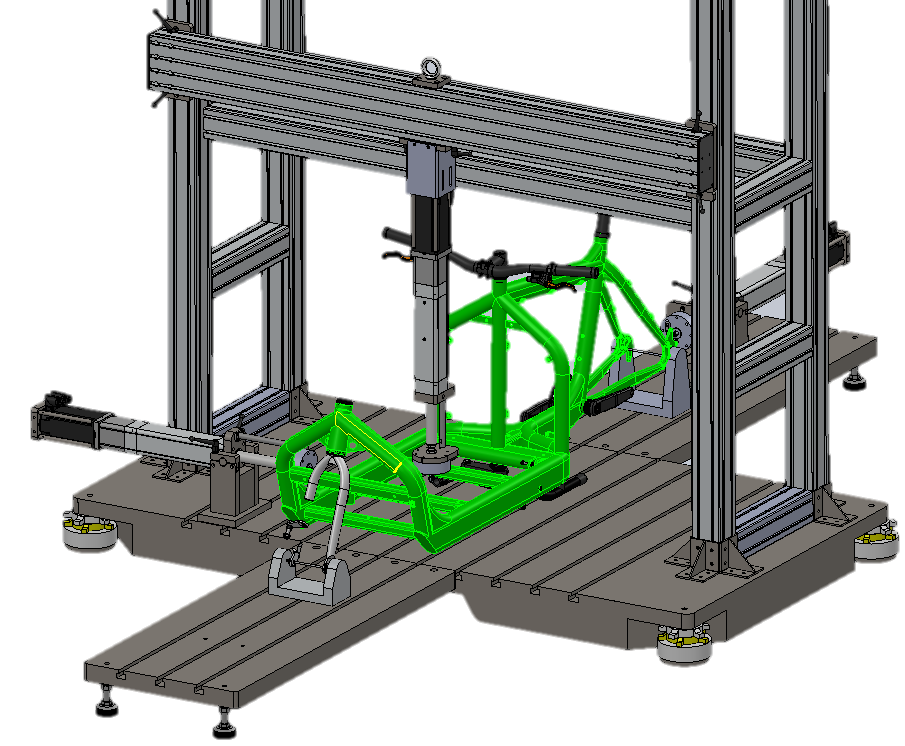

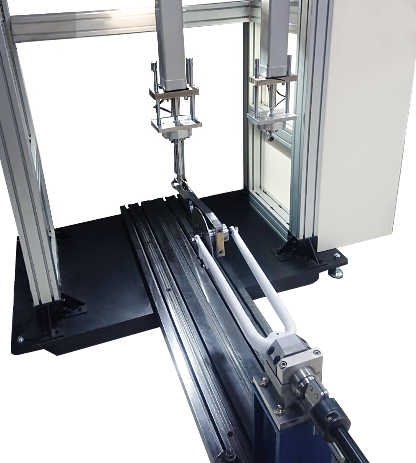

Setup examples

|

.png) |

|

|

Vertical/horizontal force in frame |

Pedaling force in frame | Customize example (Cargo bike) |

|

|

|

| Fork and stem fatigue test | Handlebar and stem fatigue test | Crank fatigue test |

|

|

|

| Seat post fatigue test | Fork disc brake fatigue test | Bottom bracket pedaling force fatigue test |

|

Item |

Hydraulic Cylinder |

Pneumatic cylinder |

Chief Si Electric actuator |

|

Force |

>10kN Beyond bicycle fatigue test requirement |

>3000N Select cylinder size per force requirement |

2600N Fully conform bicycle fatigue test requirement |

|

Stroke |

150mm conform bicycle fatigue test requirement |

150mm conform bicycle fatigue test requirement |

150mm conform bicycle fatigue test requirement |

|

Speed |

★5 m/s |

0.15 m/s |

0.45 m/s |

|

Test frequency |

★~100 Hz |

1.5 Hz@±10mm shift |

5Hz@±10mm shift |

|

Force waveform |

★Sine wave/static |

Distorting square wave |

★Sine wave/static |

|

Driving source |

Oil hydraulic pump |

Air compressor |

★220Vac power |

|

Auxiliary |

Oil pipe/Oil distribution/oil tank |

Air tank/air filter |

★No need |

|

Cooling system |

Water tower cooler/oil cooler |

Freeze Dryer |

★No need |

|

Machine dimension |

Large |

Medium |

★Small |

|

Noise |

82dBA |

82dBA |

★70dBA |

|

Green energy |

Poor |

Poor |

★Excellent |

|

Pollution |

High |

Medium |

★None |

|

Durability |

High |

Medium |

★High |

|

Leakage |

Potential oil leak issue |

Potential air leak issue |

★None |

|

Consumables |

Regular Oil/filter replacement |

Regular Filter/cylinder replacement |

★None |

|

Maintenance cost |

High |

Medium |

★Low |

Dual actuators

|

Independent control of dual actuators |

concurrently executing two tests |

|

Synchronous control of dual actuators |

available for

|

Test capability

|

Control |

Sine-wave force or stroke control |

|

Actuator force |

± 2600N |

|

Stroke |

± 75mm |

|

Force control accuracy |

±1% typical |

|

Dual actuators phase control accuracy |

±2° typical |

|

Stroke resolution |

0.01mm |

|

Testing frequency |

1-5Hz |

|

High efficiency |

|

|

High Safety |

monitoring actuator limit position and current, motor temperature, emergency stop, testing force and part deformation |

Dimension/weight/power

|

Machine dimension width*depth*height |

1500*800*2400 mm |

|

Control cabinets width*depth*height |

500*600*1200 mm |

|

Testing space |

|

|

Weight |

Machine 1000kg/control cabinets 80kg |

|

Power |

220Vac / single phase 30A |

If you are interesting this products, please download the catalog now. A sales representative will contact with you as soon as possible

© 2019 Chief SI INC. - Design By Armlet